In today’s fast-paced work environments, safety is more crucial than ever. As businesses evolve, so do the challenges of maintaining safe, secure spaces for employees and visitors. Slips and falls remain a significant concern, particularly in industrial and commercial settings. That’s why equipping modern workspaces with effective anti-slip solutions is not just a necessity—it’s a responsibility.

Let’s explore the latest and most popular anti-slip technologies, including our highly effective Anti-Slip Clips for Grating Surfaces. These innovative solutions are designed to enhance safety across various areas, from stairways to walkways, ramps, platforms, ladders and catwalks. We’ll also highlight other advanced technologies that can complement our offerings in areas where we may not have a solution.

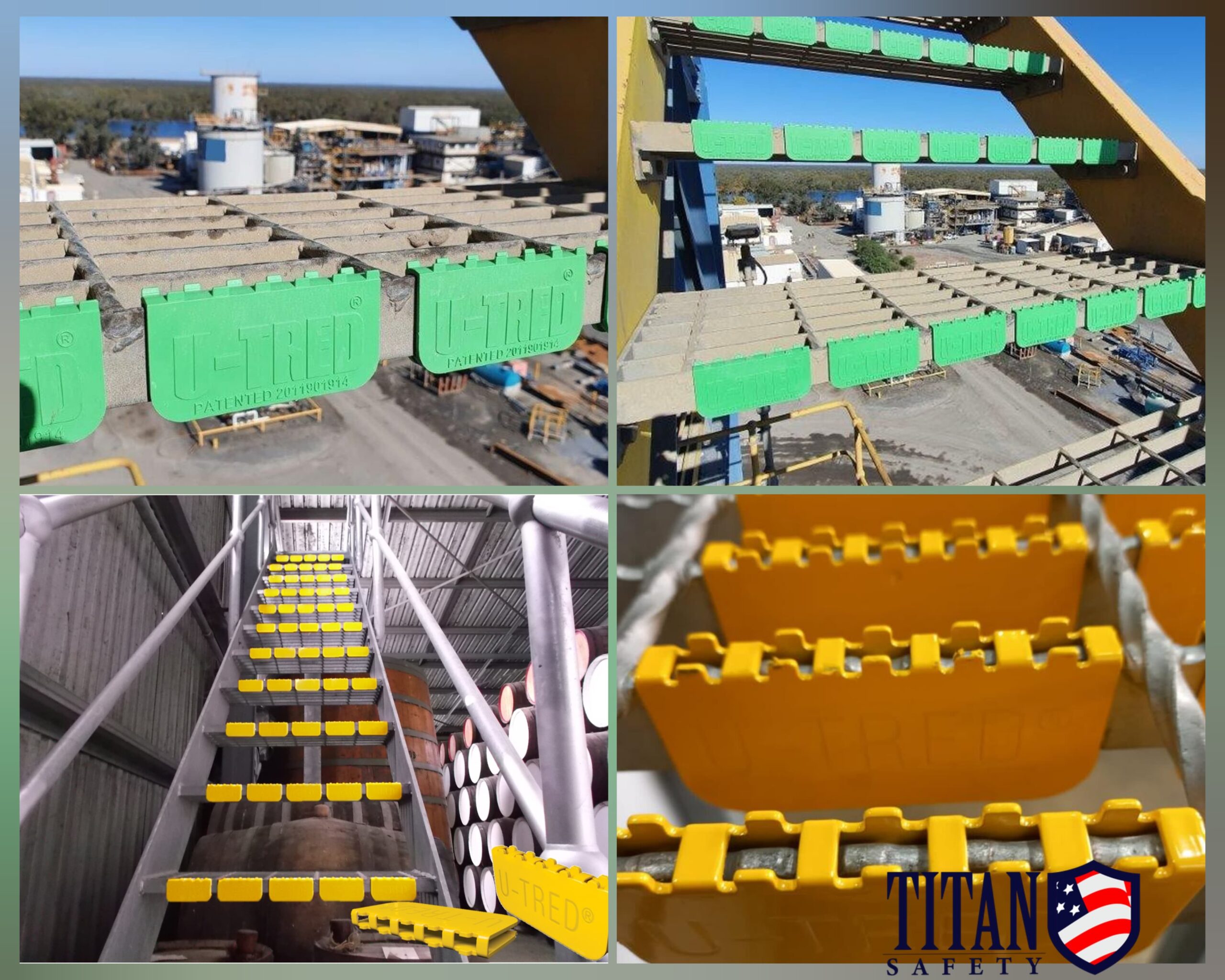

At Titan Safety, we’re committed to providing cutting-edge safety solutions that meet the demands of today’s workplaces. Our Anti-Slip Clips for Grating Surfaces are a prime example of this commitment. Designed with versatility and ease of use in mind, these clips offer a quick and effective way to enhance the safety of various areas in your workspace.

These clips are perfect for environments where safety and efficiency are paramount. By instantly improving traction and visibility, they help prevent slips and falls, making your workplace safer for everyone.

While our Anti-Slip Clips are an excellent solution for many areas, there are other innovative technologies available that can enhance safety in spaces where our clips may not be the best fit. Here are some of the most popular options:

Epoxy anti-slip coatings are a popular choice for creating durable, textured surfaces in high-traffic areas like warehouses, industrial plants, and commercial spaces. According to recent insights from Alpine Painting, innovations in epoxy coatings have significantly enhanced safety and performance, making them an excellent solution for modern workspaces .

Epoxy coatings are ideal for large floor areas that require a seamless, slip-resistant surface, such as factory floors, loading docks, and production areas.

Stair nosing’s are protective strips that are installed on the edge of steps to enhance grip and visibility. They are typically made from materials like aluminum, PVC, Steel, or Fiberglass and are designed to prevent slips on stairways.

Stair nosing’s are essential for any stairway, particularly in areas with heavy foot traffic.

Ladder rungs with anti-slip properties are crucial for maintaining safety when working at heights. These rungs are typically made from steel or fiberglass with a textured surface to provide extra grip.

Anti-slip ladder rungs are ideal for ladders used in construction, manufacturing, and maintenance environments where safety is critical.

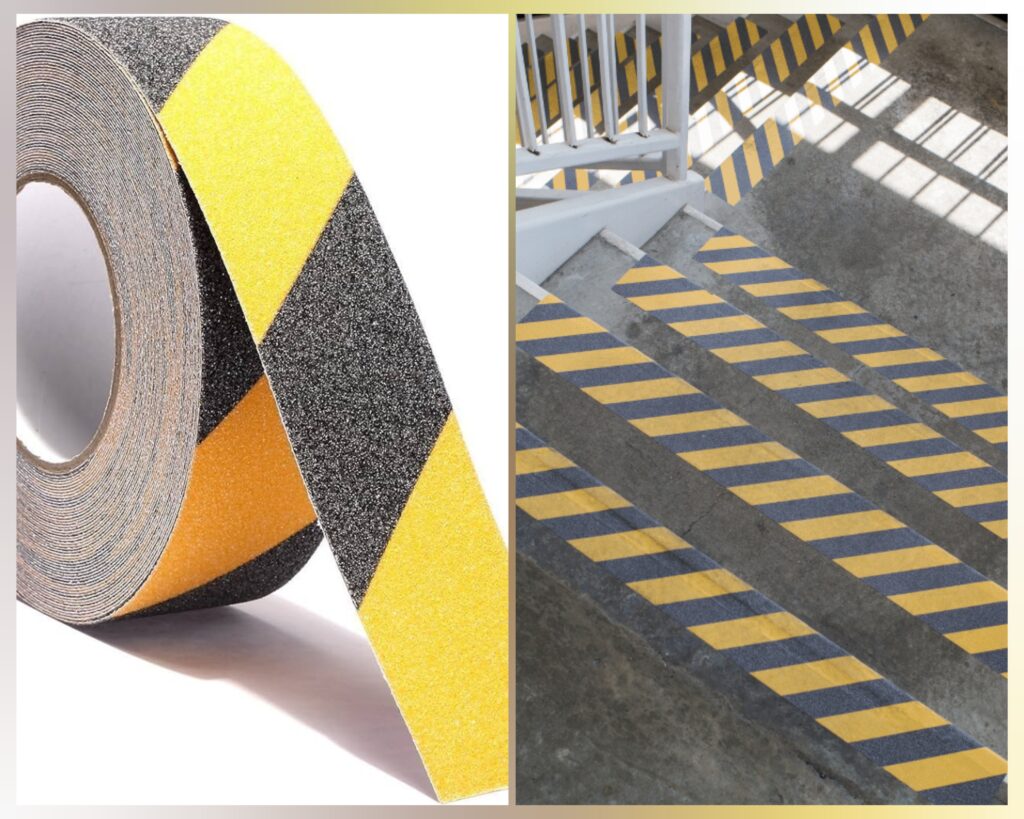

Anti-slip tape is a versatile and cost-effective solution for improving traction on various surfaces. It’s easy to apply and can be used on stairs, walkways, ramps, and more.

Anti-slip tape is perfect for quick fixes or in areas where a temporary solution is needed, such as in maintenance work or event setups.

Beyond the technologies mentioned above, there are other emerging anti-slip solutions worth considering:

In modern workspaces, safety is non-negotiable. By incorporating innovative anti-slip technologies you can create a safer, more secure environment for everyone.

Visit Titan Safety Shop to explore our full range of safety products and learn how we can help you equip your workspace with the latest in anti-slip technology.

Titan Safety is the leading provider of anti-slip solutions in the USA and Canada.

1005 N. Commons Drive,

Aurora, Illinois,

60504, USA.

Titan Safety is a global provider of specialist industrial supplies for over 40 years supplying countries such as North America, Canada and Europe.

1005 N. Commons Drive,

Aurora, Illinois,

60504, USA.