Open metal grated flooring has become a core feature of facility sites across many heavy industries. It is used as a boardwalk to keep feet off an oily, slippery floor – or as catwalks and ramps to provide access to higher levels of storage or machinery.

The open mesh design prevents a build-up of debris and surface contamination, two of the major causes of slip accident risk at work.

Despite this, there are many slip hazards remaining on metal grate flooring. Factors such as slope incline, type of facility, on-site contaminants and other environmental factors such as rain or ice mean that additional safety measures often need to be taken to prevent slips and trips.

Serrated bar grating is often sold as a slip-resistant safety floor grating. Whilst there is little doubt that it does indeed have more traction than a smooth bar grating, it might surprise you that there is a higher risk of slipping than first appearances. In fact, it seems to have surprised Tribologists (scientists studying the interface between two surfaces; friction, wear, and lubrication – aka “slippery-ness and friction”) who were conducting a scientific study of slip risk on inclined metal grating ramps.

They selected three commonly used floor gratings installed in mines and quarries, which often need inclined ramps to enable worker access to the entire length of conveyor belts and washplants and other large mineral processing facilities.

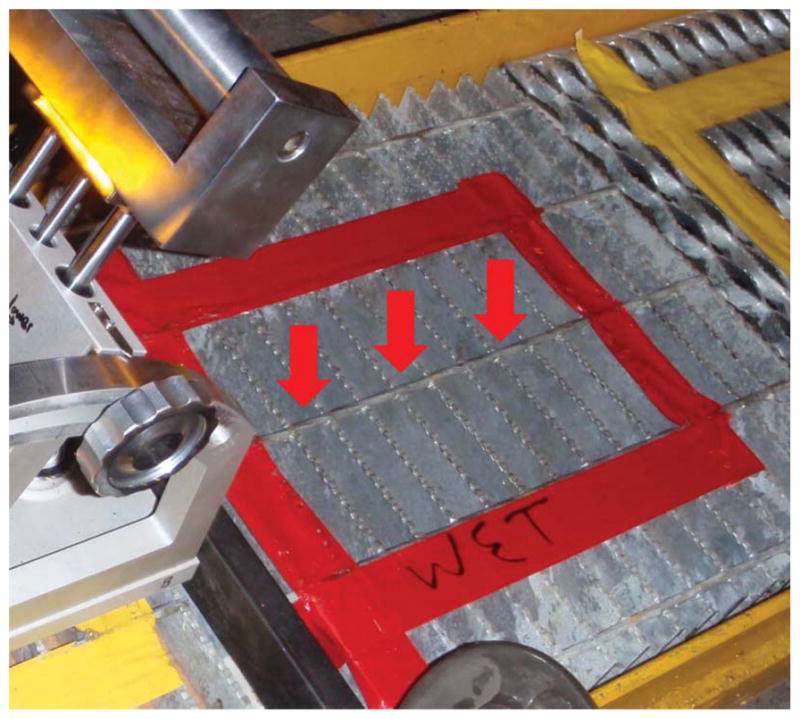

Included in this slip probability study was one of the most popular welded metal bar grating types. This Industrial Standard grating is made from flat steel bearing bars, joined together by metal spacer rods. Used in the study was the serrated bar type (Ser-bar), as the smooth surfaced metal grating is not commonly used as a floor surface in external workplaces such as mine and quarry sites.

When the scientists first used their slip-o-meter on the bar grating, they discovered that the bar gave the surface such a low slip-resistance that they decided to re-orientate the grating and slip-meter to side-step it all together.

The Authors of this metal grated flooring slip-probability study suggest that welded bar grating has a significantly increased slippage risk when used on angled ramps and inclined walkways.

Access ramps made from metal grated flooring with a slope incline “exceeding 10° should be closely monitored due to the increased risk for slip events.” say the scientists.

Practically, this might mean you need to add additional traction on such slopes and record your mitigating control in your workplace Risk Assessment.

Horizontal walkways can quickly become hazardous if contaminated by grease, oil, water etc so this should be considered as part of your risk management. Furthermore, typically the minimum safe tread depth for shoe and boot soles is 2mm so the serrated edges should protrude by at least this amount from the smoother spacing cross bars.

If your metal grating walkway has worn smooth, or was made with the rounded bar protruding too high, then do you need to replace it? Probably not, as the Titan Anti-Slip clamps can be quickly retrofitted to give your grated slopes, catwalks and industrial steps better traction in a fraction of the time and cost.

Titan Safety is the leading provider of anti-slip solutions in the USA and Canada.

1005 N. Commons Drive,

Aurora, Illinois,

60504, USA.

Titan Safety is a global provider of specialist industrial supplies for over 40 years supplying countries such as North America, Canada and Europe.

1005 N. Commons Drive,

Aurora, Illinois,

60504, USA.